Homebrewing Coffee – Part One: Beans, Processing, and Distribution

Homebrew aficionados have long celebrated the art and science of crafting their own beer, wine, mead, cider, kombucha, tea, and a variety of other beverages. Each batch represents a personal journey of patience, precision, and passion. But there’s another familiar but often overlooked actor in this homebrewing story — coffee. Revered for its rich aroma and the morning ritual we experience and see every day, coffee is more than a daily beverage; it’s a cultural cornerstone. Across the United States, it’s as ubiquitous as it is diverse, reflecting the country’s multifaceted character in every customer’s order.

For homebrewers, the step into homebrewing coffee is a natural progression, an extension of our craft into new yet familiar territory. It’s an exploration of a daily ritual through the lens of a craftsman, understanding the beans, the roast, the grind, and the brew, each a variable in the equation of flavor. This journey into coffee brewing is not just about mastering another beverage; it’s about enriching the craft of homebrewing with one of our most universal and cherished beverages. Let’s wander into the world of homebrewing coffee and rediscover how this new player complements our community through the shared language of art and science.

Coffee Varieties and Origins

Like hops and grapes, coffee beans come from regions that impart distinct characteristics to their taste and aroma:

- South America: Beans from Brazil are known for their smooth, nutty, and chocolatey flavors, ideal for espresso blends. Colombian beans are prized for their balanced sweetness and medium acidity.

- Africa: Ethiopian beans are renowned for their floral and fruity notes. Kenyan beans are favored for their bright acidity and rich berry flavors.

- Asia: Indonesian beans have earthy and full-bodied profiles, with a distinct spiciness or smokiness. Vietnamese robusta beans are stronger, more bitter, and less acidic.

Harvesting and Processing Techniques

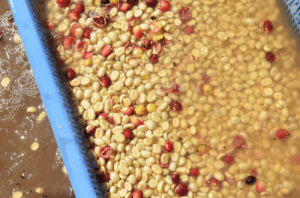

- Washed Processing:After harvesting, the coffee cherries are depulped to remove the outer skin. The beans, still encased in mucilage, are then fermented in water tanks to break down this layer. Finally, the beans are washed and dried. This method is used to create a clean, consistent flavor profile. It typically highlights the bean’s acidity and allows its intrinsic characteristics to shine.

- Fermentation time can vary, impacting flavor.

- Requires a significant amount of water and careful waste management.

- Produces a very uniform and high-quality bean.

- Natural Processing:The whole cherries are spread out to dry in the sun, either on large patios or raised beds. The drying process can take several weeks, during which the cherries must be regularly turned to prevent mold and overfermentation. This is one of the oldest methods of processing coffee. It often imparts a heavier body and sweeter, fruitier flavors to the coffee, as the bean absorbs sugars and other compounds from the cherry.

- Requires less water but more space and labor for drying.

- Weather conditions greatly influence the quality of the drying process.

- Can produce complex flavor profiles, but with less consistency than washed coffees.

- Honey Processing:A hybrid method where cherries are partially depulped, leaving some mucilage on the bean. The beans are then dried with this sticky layer intact, often resulting in a “honey-like” appearance, called Yellow, Red, or Black. This method aims to combine the best of both washed and natural processing. It typically results in a sweet, well-balanced cup, with more body than washed coffees and cleaner flavors than natural ones.

-

- The amount of mucilage left on the bean can vary, leading to different classifications.

- Requires careful monitoring during drying to prevent spoilage.

- Offers a unique flavor profile, often with a good balance between sweetness and acidity.

After coffee beans have been processed using dry, wet, or honey methods, they go through several more steps before ending up on our retail shelves.

Post-Processing to Packaging

- Drying to Optimal Moisture Content: After processing, beans are dried until they reach an optimal moisture content, typically between 10-12%. This is crucial to prevent mold and ensure longevity.

- Hulling and Sorting: Beans are then hulled to remove any remaining layers of parchment or dried cherry. They are also sorted to remove defective beans and graded according to size and quality.

- Packaging for Export: The green (unroasted) beans are typically packaged in large burlap or jute sacks, which can hold up to 60-70 kg of coffee. Some exporters use special hermetic bags inside the burlap sacks for protection against moisture and pests.

Shipping and Distribution

- Export and Import: Beans are shipped from the country of origin to the importing country. This is usually done in shipping containers via sea freight, a process that can take several weeks.

- Roasting: Once they arrive at the destination, beans are often distributed to roasters. Roasting is usually done relatively close to where the beans will be sold or consumed to ensure freshness.

- Packaging for Retail: After roasting, beans are packaged for sale. This often involves packaging them in bags equipped with one-way valves to allow gases to escape without letting air in, preserving the beans’ freshness and flavor.

- Distribution to Retail Stores: Packaged coffee is then distributed to retail stores or directly to consumers through online platforms.

Storage After Purchase

- Keep Them Cool and Dry: Store the beans in a cool, dry place away from direct sunlight. Excessive heat or moisture can degrade the quality of the beans.

- Air is the Enemy: Keep the beans in an airtight container. Exposure to air can accelerate oxidation and stale the beans. Avoid plastic containers as they can impart off-flavors to the coffee.

- Avoid the Fridge or Freezer for Short-Term Storage: For short-term storage, avoid the fridge or freezer as the fluctuating temperatures can cause condensation and degrade the bean quality. However, for long-term storage, freezing beans in airtight containers and in small batches can preserve freshness.

- Buy in Small Quantities: It’s best to buy coffee in small quantities that can be consumed within 2 to 3 weeks from roasting to enjoy it at its peak flavor.

I hope you found this view of coffee processing and packaging to be an interesting addition to your homebrewing repertoire! By following these steps and storage tips, you can ensure that your coffee maintains its quality and flavors, providing the best possible cup every time you brew. Check out our next installment of the coffee adventure in Homebrewing Coffee – Part Two: Roasting. If you’re ready to up your homebrewed coffee game right now, check out our supply of coffee equipment and ingredients! Happy brewing!