I was today years old when I learned about “Brett”!

In my head, Brettanomyces was something akin to bacteria that makes beers sour and forever commits your fermenter to sour beers. I recently found out that doesn’t have to be the case, so I set out to do a little research.

Brett is a very interesting variety of yeast. According to Wikipedia, it was discovered in 1889, and was actually the first patented microorganism in history by Carlsberg in 1903. Contrary to some beliefs, Brett does not inherently sour beer. While it can produce acidic compounds, the sourness in beer is more often attributed to bacteria such as lactobacillus and pediococcus. Brettanomyces adds complexity, offering flavors that range from fruity to funky, depending on the strain and brewing conditions.

It’s a myth that Brett is a bacteria or that it irreversibly infects brewing equipment. Brett is a yeast like saccharomyces, but it can survive in lower pH environments where sacc can’t. While it can be more resilient and difficult to eliminate than standard brewing yeasts, proper sanitation methods can effectively manage it.

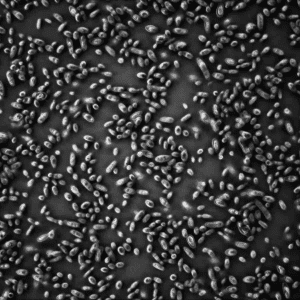

Image of Wyeast 5526

Brettanomyces Strains

There are many strains of Brettanomyces, each contributing its unique characteristics to beer. Here are a few popular ones:

Brettanomyces Bruxellensis is known for producing more of the classic “Brett” characteristics, eg a funky, barnyard, or horse blanket aroma, which is highly sought after in certain beer styles like Belgians, especially Lambics and Flanders Reds. Additionally, it can produce fruity esters, particularly when fermented at warmer temperatures, contributing to complex flavor profiles.

Brettanomyces Clausenii tends to be more subtle compared to bruxellensis. It often imparts a lighter, fruitier profile with less of the intense barnyard funk. It brings notes of tropical fruits like pineapple and a mild earthiness. This strain is a good choice if you want to introduce Brett characteristics without overwhelming the beer’s base flavors. It’s often used in American Wild Ales and other experimental styles where a balance of fruitiness and funk is desired.

Using Brett

In homebrewing, Brett can be used as either the primary or secondary fermenter. When used as the primary yeast, it ferments the beer completely, often resulting in a drier and more attenuated beer. As a secondary fermenter, Brett consumes sugars that the primary yeast left behind, adding complexity and evolving the beer’s flavor over time. Brettanomyces can take longer to ferment beer compared to traditional yeast, sometimes requiring several months to a year for the full effect.

Cleaning

As mentioned above, special attention to cleaning and sanitization is crucial after using Brett to prevent cross-contamination with future non-Brett batches.

Here are steps to ensure thorough cleaning:

- Physical Cleaning: Begin by physically cleaning all equipment that came into contact with the Brett beer. This includes fermenters, airlocks, tubing, bottles, kegs, and any other tools used. Use a good brewery wash or a cleaner like PBW to remove any organic material.

- Chemical Sanitization: After physical cleaning, use a strong sanitizer. Star San and Iodophor are effective against a wide range of microorganisms, including Brett. Ensure that all surfaces have prolonged contact with the sanitizer according to the sanitizer’s instructions.

- Consider Dedicated Equipment: Some homebrewers do opt to have separate sets of equipment for Brett and non-Brett beers. Items like plastic fermenters, tubing, gaskets, and plastic bottling equipment are relatively inexpensive and can harbor scratches where Brett can reside. Having dedicated equipment for Brett batches does reduce the risk of contamination.

- Check Gaskets and Seals: Pay special attention to gaskets, seals, and any other parts of your equipment where Brett could hide. These might need more rigorous cleaning or replacement if they’re old or damaged.

- Record Keeping: Keep track of which equipment was used for Brett batches. This can be helpful in managing your equipment and ensuring proper cleaning routines.

Wrap It Up!

While both Brettanomyces cruxellensis and Brettanomyces clausenii can add complexity and unique characteristics to beer, their distinct profiles and behaviors mean they cater to different brewing needs and preferences. And, proper cleaning and sanitization help to ensure that your next batch doesn’t get the brett touch too.

Have you used Brett in your homebrewing adventures? If so, tell us about the style you brewed, how and when you used brett in the fermentation, and what you learned in the process.